Mavenclad (cladribine tablets) for the Treatment of Relapsing-Remitting Multiple Sclerosis

Mavenclad™ (cladribine tablets) is a selective immune reconstitution therapy indicated for the treatment of active relapsing multiple sclerosis.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

As a medium-sized pharmaceutical contract manufacturing company with around 125 employees, Lomapharm® specialises in the production of tablets and liquid pharmaceuticals, including aseptic filling of eye drops and nose drops without preservative agents.

Lomapharm is located in Emmerthal in Weserbergland near Hameln, Germany. Founded as long ago as 1878, this family-run company is now managed by the fourth generation. The proactive investment strategy of the family that owns Lomapharm ensures that the company always fulfils the increasing demands of national and international markets. All of the production at Lomapharm complies with GMP standards.

Lomapharm delivers between four and six billion tablets per year to national and international customers. The versatile range of machines enables the company to produce mixtures for direct tablet compression, but also granulates – via dry granulation or wet granulation with subsequent drying.

Tabletting is carried out by a range of computer-controlled presses with a capacity of up to 320,000 tablets per hour. Coating takes place in four state-of-the-art drum coaters with up to 500kg capacity. The ‘art of sugar coating’ is performed in up to 28 modern tablet coating pans with capacities of up to 125kg each. This enables Lomapharm to process small and large batches of high-quality film- and sugar-coated tablets according to the specific demands of customers.

Since 2010 Lomapharm has been in the position to handle microtablets and to offer the service of contract manufacturing of such solid dosage form. Microtablets are small tablets with a diameter of 2mm combining the dosage advantages of granules or powders with the advantages of classical tablet manufacturing.

Lomapharm produces both solutions and sophisticated suspensions in batches up to 2.9t – also under nitrogen depending on the specific product. Several high-speed filling lines ensure perfect filling of bigger batches; smaller and mid-sized batches are filled by modern, maximal automated and very flexible filling-lines.

Filling under aseptic conditions without preservatives requires special care. Lomapharm has modern clean rooms which comply with the increasingly stringent specifications laid down for sterile production.

Beyond classical packaging of tablets into blister and tins and liquids in bottles of different and specific shape, Lomapharm offers stick packs for solid and liquid dosage forms, PET single-use drink shots, wrap-around functional labels, and of course final packaging into folding cartons or clinic packages and ‘Track & Trace’ solutions.

The range of services is rounded off by a broad spectrum of additional services such as the development and galenic optimisation of pharmaceutical formulations, design of dietary supplements, up-scaling, stability testing pursuant to ICH regulations, and support in approval application procedures.

Mavenclad™ (cladribine tablets) is a selective immune reconstitution therapy indicated for the treatment of active relapsing multiple sclerosis.

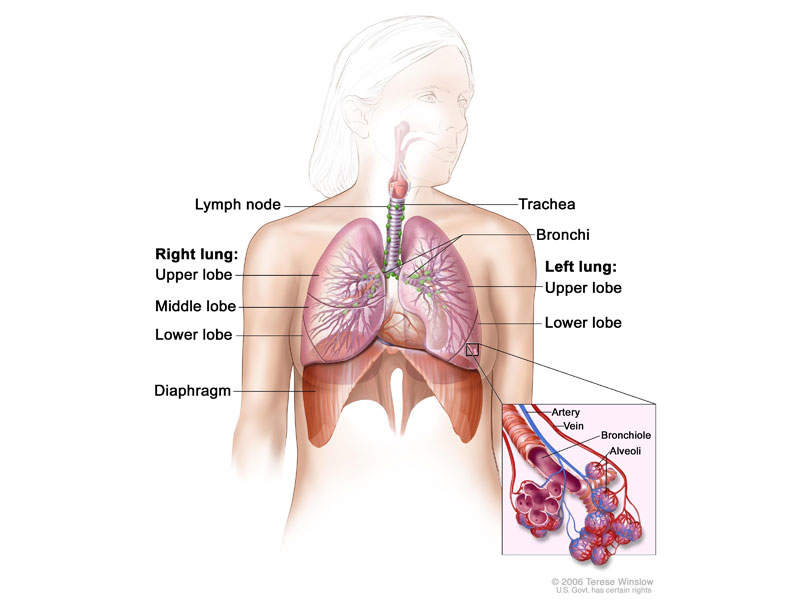

Alecensa (alectinib) is a kinase inhibitor intended for the treatment of patients with anaplastic lymphoma kinase (ALK)-positive non-small cell lung cancer (NSCLC).

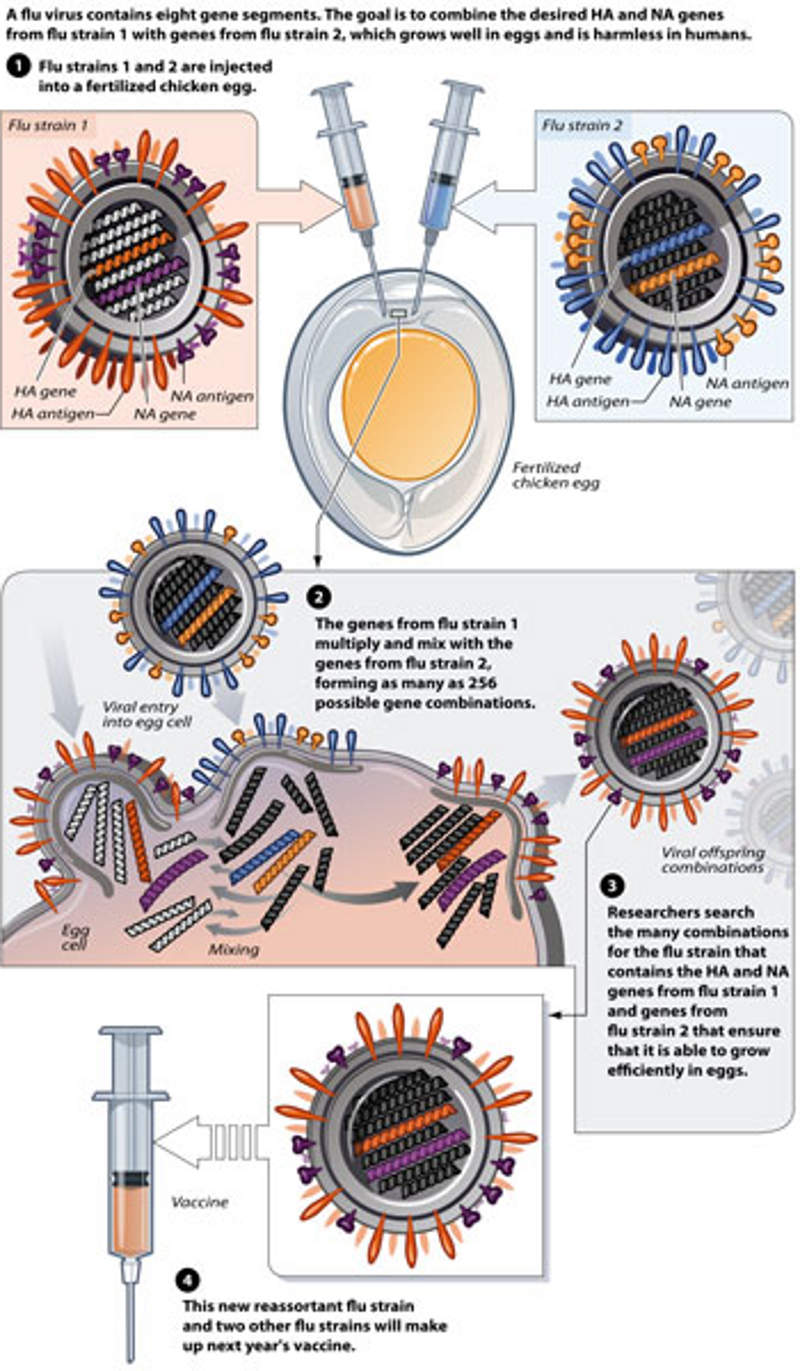

Afluria Quadrivalent is an inactivated influenza vaccine developed by Seqirus, which is developed to provide active immunisation against the disease.

Descovy (emtricitabine200mg/tenofovir alafenamide25mg, F/TAF) is developed by Gilead sciences for the treatment of HIV-1 infection in adults and children above 12 years of age.

Keveyis (dichlorphenamide) is the first medicine indicated for the treatment of primary hyperkalemic and hypokalemic periodic paralysis, which are a group of rare hereditary disorders that cause occasional episodes of muscle weakness or paralysis.